|

|||||||||

Extra Data for Kit 17.1 and 17.2

|

|||||||||

|

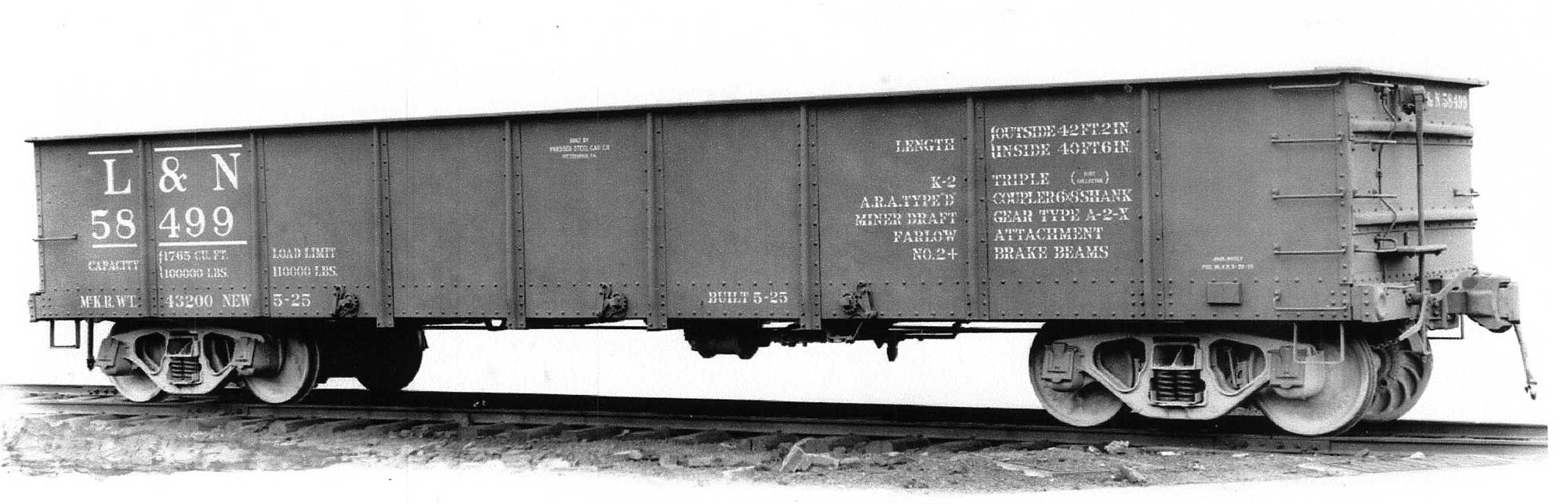

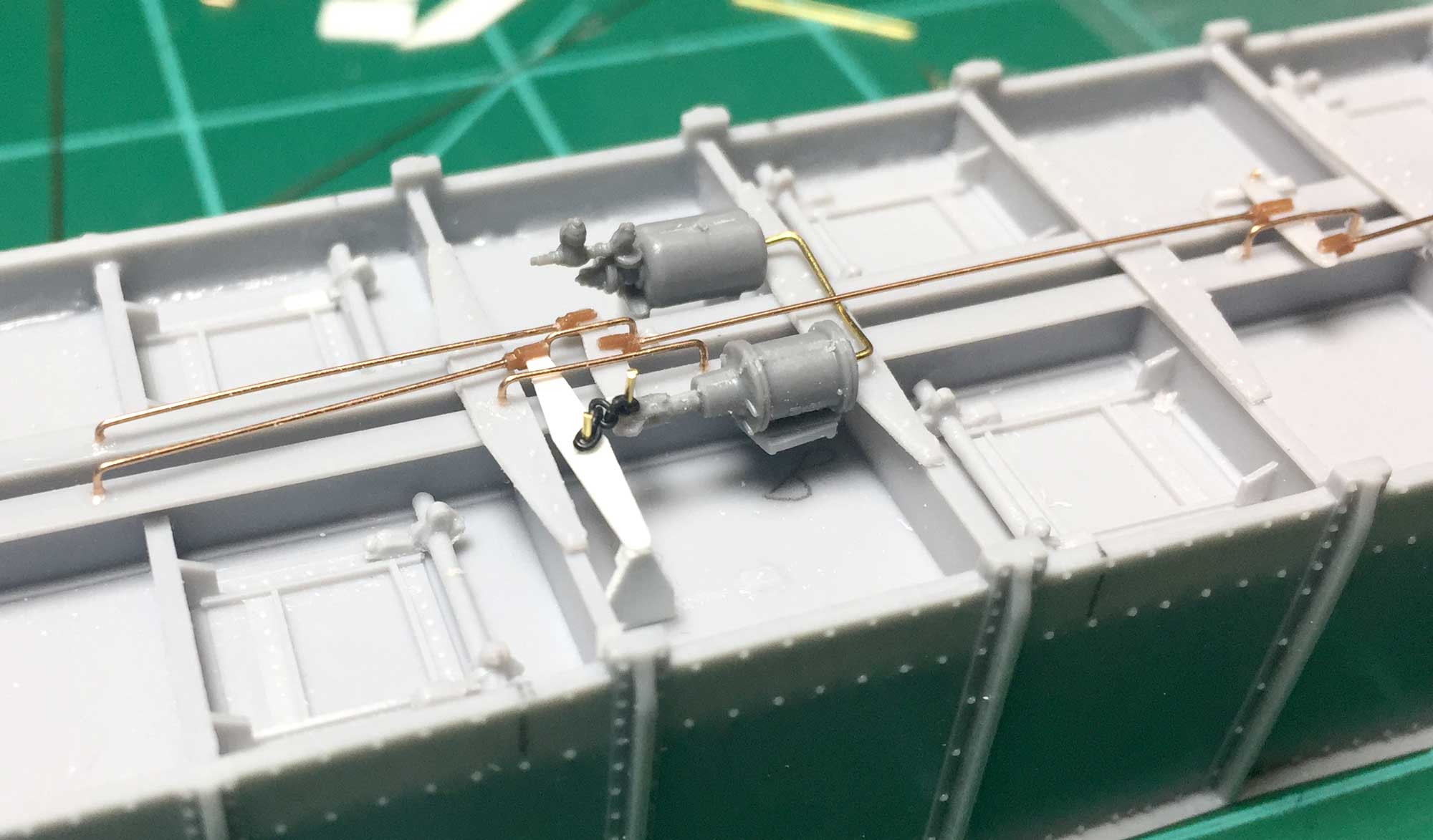

Resin Car Works would like to thank the following rail historians and modelers for their high quality work. Without their efforts, these kits would not have been produced. Tom Madden - casting work There were two versions of this kit. Kit 17.1 included decals for the as-built lettering. These files are intended to help you build our models. Prototype images Split-K brake installationHere are a couple photographs from Eric Hansmann to help with the split-K brake component installation. Scrap styrene was used as pedestals to mount the air reservoir. The connection between the air reservoir and brake cylinder is 0.015-inch diameter wire. The long brake lever was made from 1x8 styrene. It rests on scrap styrene at the pivot point. This is mounted closer to the cross member as the lever should be nearly parallel to the cross member. A short length of chain connects the long brake lever with the brake cylinder clevis. Holes were drilled in the long brake lever and the top of the brake cylinder clevis for small diameter wire pins. The ends of the chain are positioned over the pins and glued. The excess pin length is trimmed after the glue sets up. The photo above was snapped before the glue had set. It's possible that many of these L&N gondolas retained their original brake systems into the 1940s. The K brakes would only be replaced with an AB system when the cars underwent a major rebuild.

|